ABOUT US

Strong strength · Excellent equipment · Quality assurance · Customer first · Win-win cooperation

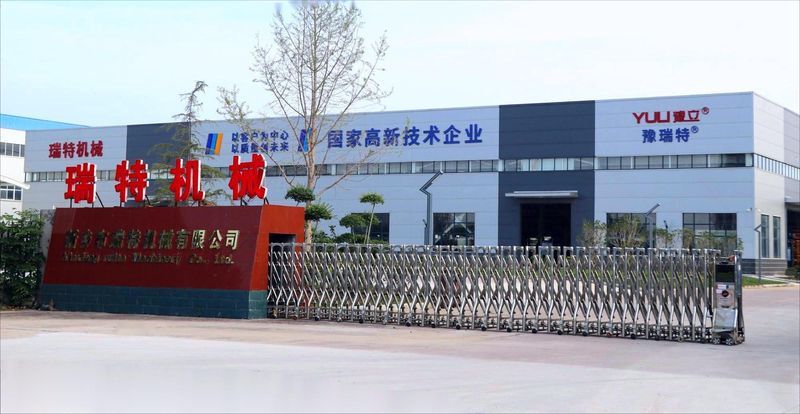

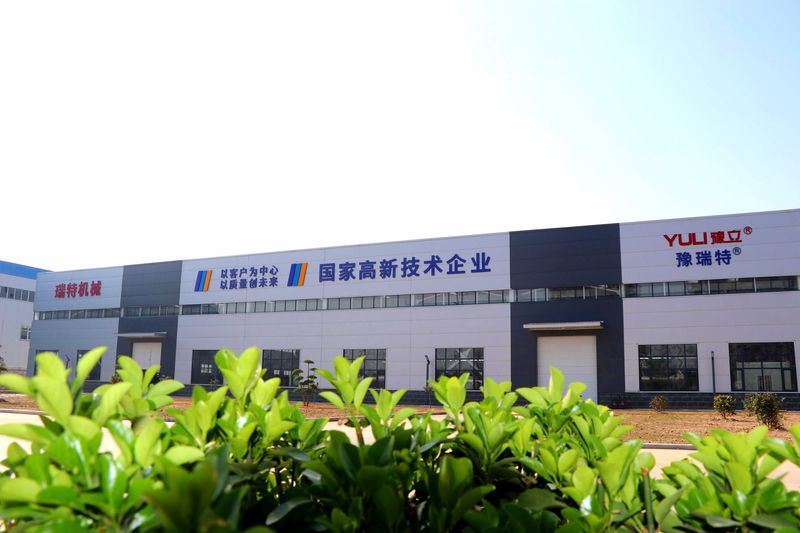

Ruit Machinery, established in 2010, is dedicated to the research,

development, and production of the prefabricated concrete industry. It is a

high-tech machinery enterprise that integrates production, installation,

manufacturing, sales, technological innovation, and after-sales guidance. Our

company has always adhered to the business philosophy of "following the right

path, being responsible, and having others in mind", and has been committed to

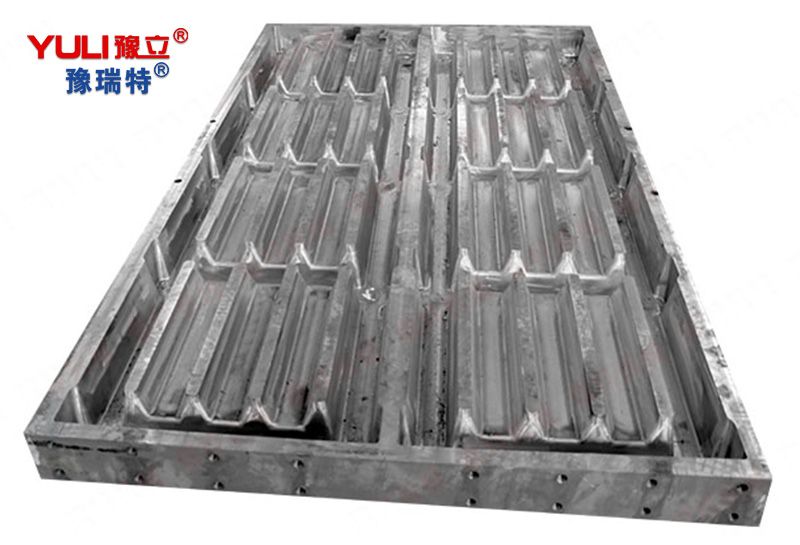

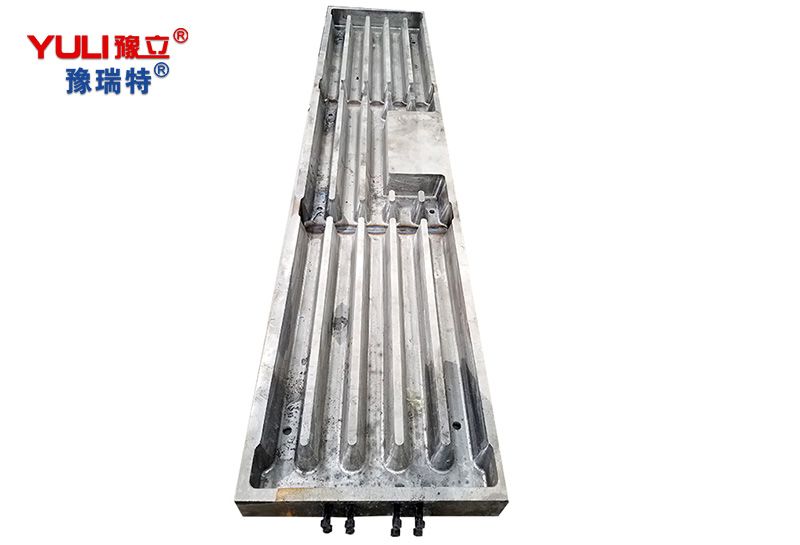

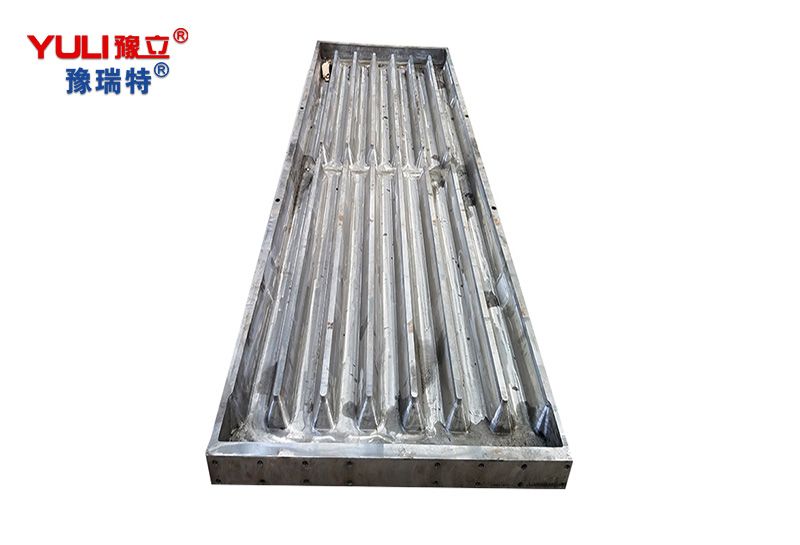

the market promotion and sales of leak-proof board production lines and

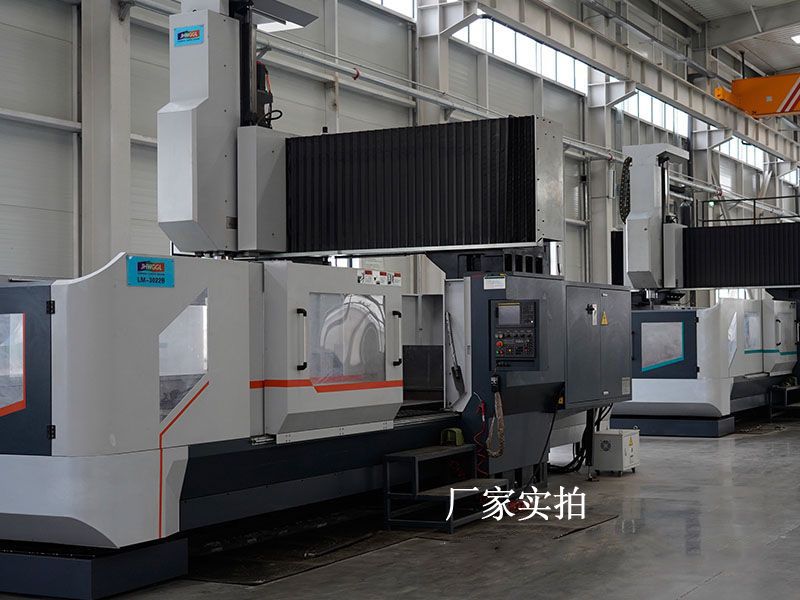

leak-proof board molds. Our company boasts a management team, R&D and design team, high-quality

sales team, and a comprehensive after-sales service team. Furthermore, we

possess a robust quality management system. By gathering elites and through the

joint efforts of all employees, our company has repeatedly received honorary

titles such as "Unit of High Quality and Trustworthiness", "Henan Quality

Integrity AAA-level Brand Enterprise", and "Civilized and Trustworthy

Enterprise". Our products currently hold multiple patents, solidifying Ruit

Machinery's technological position in the field of cement product processing

equipment. Our company adheres to the marketing philosophy of "winning the market with

quality, establishing a foothold in the market with price, consolidating the

market with service, and expanding the market with innovation", and follows the

corporate philosophy of "people-oriented, innovative and enterprising, and

common development". We serve the agricultural and animal husbandry industry,

construction industry, livestock breeding, and other industries both

domestically and internationally. We have repeatedly conducted international

strategic cooperation with livestock equipment groups from the UK, Germany,

Denmark, the Netherlands, Australia, and other countries, introducing automated

equipment production lines, which has enabled our products to sell well both

domestically and internationally, earning international reputation. So far, Ruit Machinery has served over ten thousand customers, and has been

recognized and praised by customers for its stable equipment performance in

project applications, achieving a leap forward in the industry. "Yuli" construction machinery, surprisingly, is in Ruite. Achievements

belong to the past, while goals are still in the future. Ruite is willing to

sincerely cooperate with people of insight from all walks of life to achieve

common development and win-win results.

MORE

-

2010Y

established in

-

50+

active employee

-

800W

Registered capital

-

80+

Main products

-

3000m²

floor area