1、 Project positioning and core value: Winning through scale

Strategic positioning: With an annual production capacity of 100000 tons,

it aims to become a core fertilizer supply base or regional organic waste

centralized treatment center serving provincial and even cross regional markets.

The project has strong raw material consumption capacity and market

influence.

Raw material matrix: The core process can efficiently and collaboratively

process various organic solid wastes such as livestock and poultry manure,

municipal sludge, kitchen waste, crop straw, food processing waste, etc.,

achieving true "urban mineral" development.

Multidimensional value:

Economic benefits: Large scale production dilutes unit costs, enhances

brand premium ability, and significantly increases profit margins.

Environmental benefits: becoming a key part of urban environmental

infrastructure, large-scale waste disposal, reducing pollution and carbon

emissions.

Social benefits: Stable supply of high-quality organic fertilizers,

assistance in soil improvement and food security, and creation of a large number

of job opportunities.

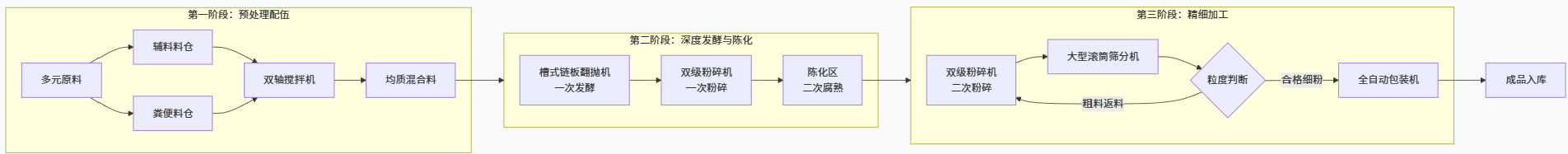

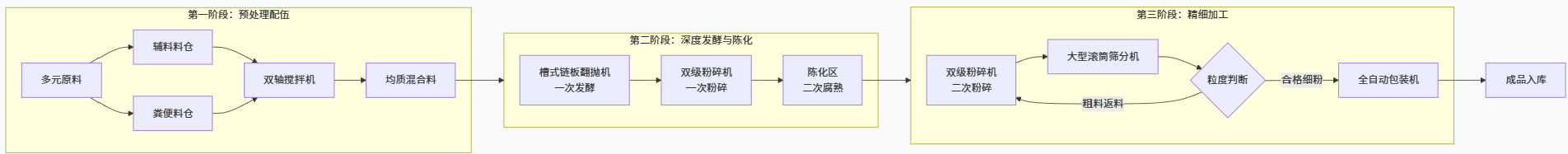

2、 Core process flow: three-stage deep treatment system

The 100000 ton project is not a simple amplification of a small-scale

production line. Its core lies in the introduction of a more refined three-stage

system of "pretreatment deep fermentation refined processing", ensuring dual

high standards of output and quality.

Phase 1: Raw material pretreatment and precise compatibility system

This is the cornerstone of stability in large-scale production. The system

sets up independent auxiliary material silos and feces silos, and uses a dual

axis mixer to scientifically mix and evenly mix various raw materials.

Core objective: To precisely regulate the carbon to nitrogen ratio (C/N),

moisture, and porosity of the initial mixture, creating homogeneous and ideal

initial conditions for subsequent efficient fermentation.

Key control: Adopting an automatic batching and conveying system to ensure

consistency and accuracy in the proportioning of large quantities of raw

materials.

Phase 2: Efficient Fermentation and Aging System

This is the heart of the project, an automated fermentation workshop with a

slot type chain plate flipping machine as the core.

Technological upgrade: The chain plate flipping machine has fully automatic

PLC remote control, hydraulic lifting, and deep groove operation capabilities.

It has high flipping force, uniform oxygenation, and can quickly heat up and

maintain a high temperature of over 55 ℃, significantly shortening the

fermentation cycle.

Process deepening: Configure the "secondary maturation" process. After

initial fermentation and crushing, the material enters the secondary aging zone

for further stabilization, forming higher quality humus and significantly

improving the maturity and agricultural effectiveness of the product.

Three stages: Fine processing and intelligent packaging system

To meet the high requirements for product consistency in bulk commodities,

stronger processing capabilities will be configured in this stage.

Double crushing: Install a two-stage crusher before fermentation and after

aging to ensure that raw materials from different batches and sources can be

crushed to a uniform fineness.

Efficient screening: using a large drum screening machine to strictly

separate qualified powder and return materials, ensuring 100% sieving of the

finished product and a delicate appearance.

Intelligent packaging: The fully automatic quantitative packaging machine

realizes unmanned high-speed filling, metering, and sewing, meeting the daily

production demand of hundreds of tons of finished products.

To clearly demonstrate the flow and conversion process of this complex

material, the overall process flow can be summarized as follows:

3、 Key equipment configuration and selection points

A 100000 ton production line is an integration of heavy equipment. The

following configuration highlights its characteristics of scale, automation, and

high reliability.

| 系统模块 | 序号 | 设备名称 | 数量 | 功率 (kW) | 核心作用与选型解析 |

|---|

| 预处理系统 | 1 | 辅料/粪便料仓 | 各1台 | 3+2.2 / 11 | 独立分区投料,防止交叉污染,拨料器解决架桥问题,保证连续供料。 |

| 2 | 双轴搅拌机 | 1台 | 30 | 高 效强力混合,确保万吨级原料批次混合的均匀度,耐磨设计保障寿命。 |

| 发酵系统 | 3 | 链板式翻抛机 | 3台 | 81(每台) | 产线核心动力。多台并行覆盖大面积发酵槽,自动化运行是保障产能与工艺的关键。 |

| 精制系统 | 4 | 双级粉碎机 | 2台(前后工段) | 18.5+22(每台) | 两级强力破碎。前级处理块状腐熟料,后级确保成品细度,是品质保障的关键。 |

| 5 | 滚筒筛分机 | 1台 | 15 | 高通量精细筛分。宽体大直径设计满足大流量筛分需求,不锈钢材质防腐耐磨。 |

| 6 | 全自动包装机 | 1台 | 15 | 终点效率担当。高速高精度包装,决定成品出厂速度,必须稳定可靠。 |

| 物流系统 | 7 | 皮带输送机 | 总长约150米 | 55 | 生产线动脉。全线贯通,800mm宽皮带满足大输送量需求。 |

| 控制系统 | 8 | 配电柜 | 3套 | 0 | 系统大脑。集中控制,降压启动保护大功率电机,调速控制关键设备。 |

Reminder: Large scale production requires extremely high equipment reliability. All motors and reducers must use national standard heavy-duty products, and the warranty terms for key components such as the hydraulic system of the flipping machine and the blades of the crusher must be clearly defined. It is recommended to choose a supplier that can provide fully automatic PLC control systems and remote monitoring services.