1、 Project positioning and product strategy: diversification and high

value

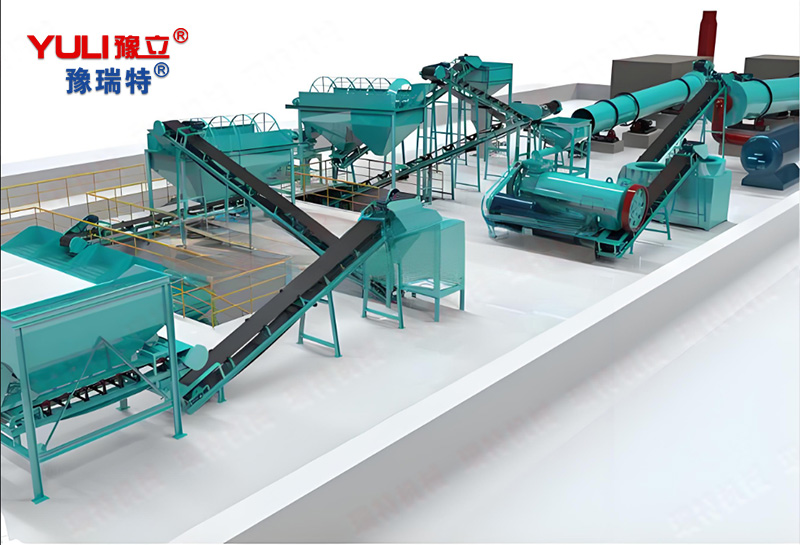

Market positioning: With a production capacity of 100000 tons of granular

organic fertilizer, it is positioned to serve the national or regional market,

meeting the demand for standardized and high-quality fertilizers from large

farms, agricultural cooperatives, and high-end economic crop planting areas.

Core raw materials: Using livestock and poultry manure (such as cow, sheep,

pig, chicken manure, etc.), municipal sludge, biogas residue, and crop straw as

core raw materials to achieve complete resource utilization of waste.

Product matrix (frontline productivity): With the strong formula and

processing capabilities of this production line, it can flexibly produce three

categories of high-value fertilizers, achieving full market coverage and

maximizing profits:

Pure organic fertilizer granules: high-quality commercial organic

fertilizer that meets national standards.

Organic inorganic compound fertilizer granules: add inorganic nutrients

such as nitrogen, phosphorus, and potassium (total nutrients ≤ 15%) to achieve a

combination of quick acting and long-term effects.

Bio organic fertilizer granules: Adding functional bacterial strains during

the granule coating stage has the biological effects of improving soil, disease

resistance, and promoting growth.

2、 Detailed explanation of core process flow: from waste to high-quality

granules

The production of granular fertilizers is a comprehensive application of

physical, chemical, and biological technologies, and the process is much more

complex than that of powdered fertilizers. Its core lies in "precise

fermentation, deep processing, and strict granulation", and the entire process

can be divided into four major system modules.

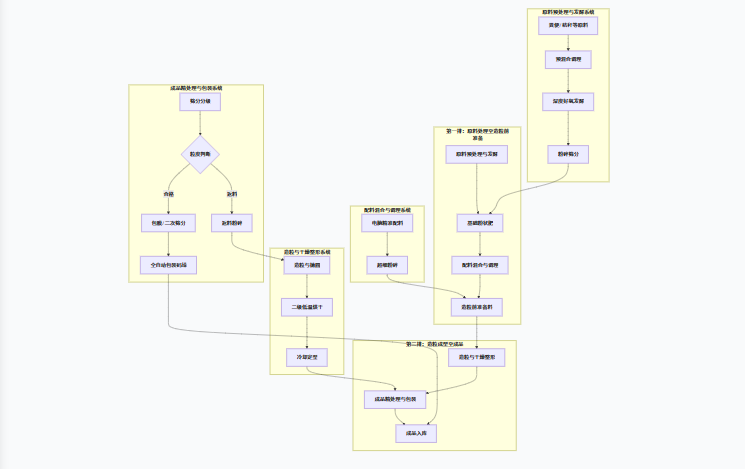

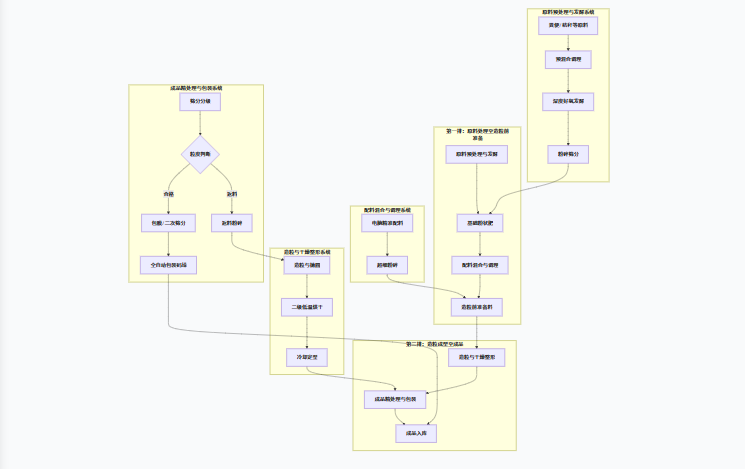

To clearly demonstrate the complete transformation path of materials from

their original state to high-quality particles, the following overview flowchart

is compiled:

The following is a detailed analysis of each core system:

1. Raw material pretreatment and efficient fermentation system

This is the cornerstone of ensuring product safety and quality.

Precise pre mixing: Feces and crushed straw and other auxiliary materials

are scientifically mixed through an independent silo and a double axis mixer,

adjusting the initial carbon nitrogen ratio and moisture content.

Deep fermentation: A fully automatic chain plate flipping machine is used

for aerobic fermentation in the fermentation tank. Through PLC control, timed

and uniform flipping can be achieved to ensure that materials are fully

decomposed and pathogens are killed at high temperatures of 60-80 ℃. This

process can effectively reduce moisture content.

Powder preparation: After being crushed by a two-stage crusher, the

decomposed clinker is sieved through a drum screen to remove impurities and

obtain a uniform powdered organic fertilizer. It can be directly packaged as

powder fertilizer or enter the granulation process.

2. Ingredient mixing and fine conditioning system

This is the "formula focus" for achieving product diversification.

Computer batching: Basic powder fertilizer, bentonite (binder), humic acid,

and inorganic nutrients such as nitrogen, phosphorus, and potassium are

accurately measured and proportioned using a multi bin computer batching

scale.

Ultra fine mixing: After the prepared materials are vigorously mixed by a

double shaft mixer, they are finely ground by a vertical crusher to ensure that

all materials have a fineness of less than 0.7mm, which is a key prerequisite

for forming uniform and solid particles in the future.

3. Granulation, drying, and cooling shaping system

This is the core physical processing step of particle molding.

Forming and polishing: Micro powder materials are agglomerated into

particles by adding a small amount of water in a granulator (disc or drum), and

then enter a polishing and shaping machine to make the particle surface smooth

and the shape regular.

Low temperature drying: Wet particles enter a two-stage series dryer and

use the "low temperature high air flow" process (inlet high temperature, outlet

temperature strictly ≤ 65 ℃) to gradually reduce the moisture content of the

particles from about 30% to 20%, effectively protecting the organic matter and

active substances in the fertilizer.

Cooling and shaping: After drying, the hot particles come into full contact

with a large amount of cold air in the rotary cooling machine, rapidly cooling

down. This process is not only convenient for storage, but also can condense

surface moisture, significantly improving particle strength and hardness, and

ultimately stabilizing the moisture content of the finished product at around

15%.

4. Finished product finishing and packaging system

This is the final check to ensure the uniformity of product appearance and

quality.

Fine screening and return circulation: After cooling, the particles are

classified by a drum screening machine. The particles that meet the

specifications (usually 2-4mm) enter the next process, while the particles that

are too large or too small are automatically sorted and crushed before returning

to the granulator for re granulation, forming a closed-loop circulation and

achieving "zero waste" of raw materials.

Coating and secondary screening (optional): Qualified particles can enter

the coating machine, spray functional bacterial solution to produce bio organic

fertilizer, or undergo anti caking treatment. Afterwards, perform a secondary

screening to ensure uniform particle size and enhance the product image.

Intelligent packaging: The finished particles are accurately measured,

bagged, sealed, and palletized by a fully automatic packaging and palletizing

production line, with unmanned operation throughout the entire process, greatly

improving terminal efficiency.

3、 Key equipment configuration list and selection analysis

The 100000 ton pellet production line is an integrated equipment for heavy,

complex, and continuous operations. Its equipment investment and complexity are

much higher than those of powder fertilizer production lines of the same

scale.

| 系统模块 | 序号 | 设备名称 | 规格型号/核心要求 | 数量(台/套) | 关键作用与选型要点 |

|---|

| 发酵预处理系统 | 1-5 | 料仓、搅拌机、翻抛机、粉碎机等 | 同十万吨粉剂线标准,确保提供优 质粉状基础料。 | 1套 | 品质源头。为造粒提供稳定、腐熟完全的原料。 |

| 配料混合系统 | 6 | 电脑配料机 | 五仓,全自动触摸屏控制。 | 1套 | 配方执行核心。精度决定产品养分含量稳定性。 |

| 7 | 双轴搅拌机 | RSJ-160,高锰耐磨螺旋。 | 1台 | 混合均匀度保障。 |

| 8 | 立式粉碎机 | RLF850型,出料细度0.7mm。 | 1台 | 造粒前关键设备。细度直接影响成粒率与颗粒强度。 |

| 造粒干燥系统 | 9 | 造粒机 | RZ-2*9,内衬耐磨橡胶。 | 1台 | 颗粒成型核心。决定初始粒形与粒径分布。 |

| 10, 11 | 烘干机 | RG-2.4*24m, RQ-22*22m,两级串联。 | 2台 | 低温脱水核心。重型结构,耐高温风机,温控精确。 |

| 12 | 冷却机 | RL2.2*22m,配大风量风机。 | 1台 | 颗粒定型设备。快速降温增硬,决定成品物理强度。 |

| 成品处理系统 | 13 | 筛分机 | RS1.8x7,不锈钢筛网。 | 2台 | 颗粒分级把关。实现成品与返料的高 效分离。 |

| 14 | 包膜机 | RM-1.5*6m。 | 1台(可选) | 产品增值设备。用于生产生物肥或防结块处理。 |

| 15 | 全自动包装码垛线 | RZ-5型,含高位码垛。 | 1套 | 终端效率体现。高速、精准,节省大量人工。 |

| 辅助与环保 | 16 | 皮带输送机 | RP800型,总长超180米。 | 1批 | 产线动脉。连贯所有工序。 |

| 17 | 除尘系统 | 旋风+迷宫+水幕三级除尘。 | 1套 | 环保必备。确保尾气排放达标,保护环境。 |

Selection warning: Drying machines, cooling machines, and granulators in particle production lines are large-scale rotary equipment, and their main material thickness, casting strength, and bearing configuration directly determine the equipment's lifespan and operational stability. It is necessary to specify the use of heavy-duty cast steel parts (rolling rings, gears, etc.) and high-temperature resistant fans. The motor and reducer must be national standard products, and key equipment must be provided with non-human damage warranty.

4、 In depth analysis of project investment and benefits

1. Investment scale estimation

The pellet production line has seen a significant increase in equipment

investment due to the addition of numerous processes such as granulation,

drying, cooling, coating, and complex screening.

Total equipment investment: The investment in core production line

equipment (excluding fermentation part) is about 4-6 million yuan. The

investment for the entire production line, including the complete fermentation

and pretreatment system, is approximately 7-10 million yuan.

Civil engineering and supporting facilities: require larger factory

buildings (including fermentation tanks, production workshops, and finished

product warehouses), more complex energy sources (natural gas or steam heating),

and environmental protection facilities, with an investment of approximately 3-5

million yuan.

Total investment scale: A well-equipped 100000 ton granular organic

fertilizer project, typically with a total investment of 10-15 million yuan or

more, belongs to a heavy asset investment project.

2. Economic benefit model

Production cost: Due to the complex process and high energy consumption,

the comprehensive cost of granular fertilizer is about 500-700 yuan/ton.

Sales price: The added value of granular organic fertilizers (especially

organic-inorganic compound fertilizers and bio organic fertilizers) is high, and

the market price is usually between 800-1200 yuan/ton, or even higher.

Profit and return: The annual output value can reach 80-120 million yuan,

and the gross profit margin is significant. Although the investment is

significant, high-quality granular fertilizers have high profit margins and

strong market competitiveness, with an expected static investment payback period

of 4-6 years. You can also actively apply for various environmental protection

and resource utilization policy subsidies.

3. Operational core and risk management

Key to success:

Proficient in technology: Fine control of process parameters such as drying

temperature, material fineness, and return ratio is required, requiring a

professional production technology team.

Quality management: Establish a comprehensive testing system from raw

materials, semi-finished products to finished products to ensure that products

meet national standards.

Brand and Channel: High value products need to be matched with strong brand

building and sales networks.

Main risks:

Technical risk: Improper process control can easily lead to low particle

formation rate, poor particle strength, drying agglomeration, and other

problems.

Market risk: We need to face competition from traditional fertilizers and

other brands of organic fertilizers.

Financial risk: Large investment amount, high requirements for the

financial chain.