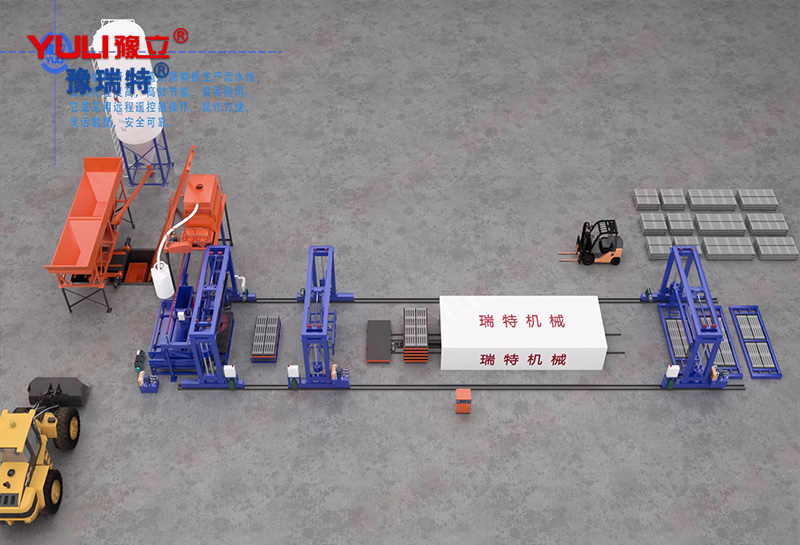

1、 Advantages of production line

1. The coils of the motors used in this device are all wound with copper

wire;

2. The electrical components used in this device are all from

internationally renowned brands such as Delixi and Chint;

3. The equipment is mainly powered by hydraulic and pneumatic systems, with

low energy consumption and easy maintenance;

4. The overall equipment is mainly controlled by automation, replacing

traditional manual operations, reducing labor, and having a low failure

rate;

5. The equipment is equipped with a thermal relay to prevent the motor from

overheating and extend its service life;

6. The equipment operates in a ground running mode, which avoids damage to

products and equipment caused by resonance phenomena compared to the traditional

sky running mode;

7. The vibration platform is made of special materials to avoid welding

seam cracking, screw loosening and other situations caused by the production

line during the production process;

8. Pneumatic demolding, convenient and fast demolding, with a complete

surface of the finished product;

9. The automatic clamping device of the fixture after power failure ensures

the safety of the operating product and personnel.

2、 Comparative analysis of production lines

1. The fully automatic dual-mode production line is remotely controlled

from material sorting to subsequent palletizing. Requires minimal labor and high

efficiency. It is currently a very popular production line;

2. Dual mode production line, capable of producing 600mm wide or 12000mm

wide leaky boards with high degree of freedom;

3. Fully automatic production line, machine fabric, uniform fabric, stable

finished product performance.