1、 Project positioning and core advantages

Scale positioning: With an annual output of 50000 tons, it is an ideal

investment scale for prefecture level markets or large agricultural and animal

husbandry groups, with significant scale effects, and can effectively cover

fertilizer demand within a radius of 100-200 kilometers around.

Product matrix: First line productivity, flexible switching according to

market demand, producing three categories of products: pure organic fertilizer

granules, organic-inorganic compound fertilizer granules (total nutrients ≤

15%), and bio organic fertilizer granules, with strong market adaptability.

Core values:

Moderate investment and stable returns: Compared to a 100000 ton production

line, the investment threshold is lower, but it can still enjoy the cost

advantage brought by large-scale production.

High end products with considerable profits: Granular fertilizers have good

form, high strength, and are easy to use, with significantly higher market

prices and profit margins than powdered fertilizers.

Environmental benchmark, policy support: The project itself is a typical

resource recycling project that complies with national industrial policies and

is easy to obtain various subsidies and support.

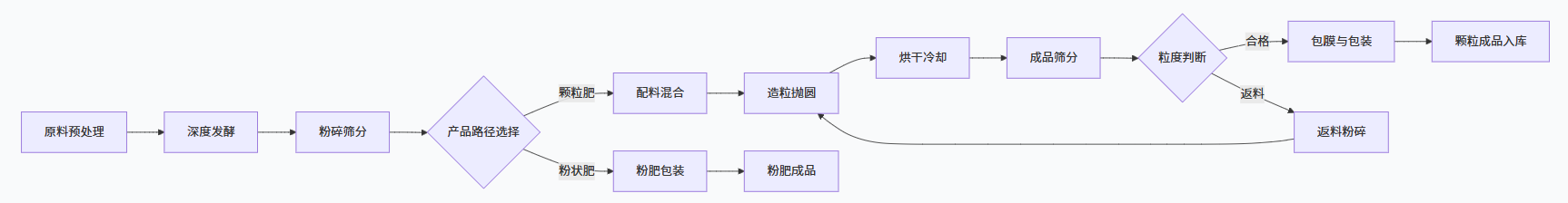

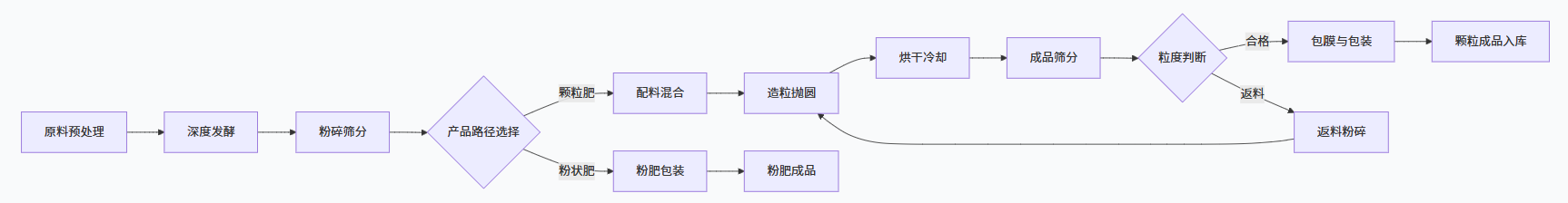

2、 Detailed explanation of core process flow

The 50000 ton pellet production line fully covers the entire process from

raw material processing to finished product packaging, and its core technology

can be condensed into four major links: "refined composting, uniform batching,

skillful granulation, and strict screening".

To present this process more intuitively and compactly, the entire process

can be summarized as the following vertical flowchart, avoiding overly broad

formatting and making it easier to read:

Process Stage Analysis:

Raw material maturation system (quality cornerstone): After pre mixing

feces and straw and other auxiliary materials with a double shaft mixer, they

enter a fermentation tank equipped with a chain plate flipping machine for deep

aerobic fermentation. Through multiple flips and throws, the temperature can

reach 60-80 ℃, completely killing harmful bacteria and producing stable and

decomposed basic powdered organic fertilizer. This is the quality starting point

for all subsequent products.

Powder fertilizer branch line (flexible output): After screening, the

powdered fertilizer can be directly made into commercial powder fertilizer for

sale through an automatic powder packaging machine, providing fast cash flow for

investment.

Particle processing system (core value):

Precise ingredients: Basic powder fertilizer is accurately proportioned

with nutrients such as bentonite, nitrogen, phosphorus, and potassium through a

five bin computer ingredient system, achieving product diversification.

Homogenization and ultrafine: The prepared material is subjected to

secondary mixing and a chain crusher to ensure uniform fineness (up to 0.7mm),

which is the key to particle size and strength.

Forming and drying: The material is formed in a granulator, smoothed by a

rounding machine, and then enters a two-stage series dryer. Adopting the

"low-temperature high air flow" process (inlet high temperature, outlet

temperature strictly ≤ 65 ℃), efficient dehydration is carried out while

protecting the activity of organic matter, and then rapidly cooled and shaped by

a cooling machine.

Finished product refining system (product guarantee): After cooling, the

particles are classified by a screening machine. Qualified products can be

coated (for producing biological fertilizers) and screened again to ensure

uniform particle size (2-4mm). Finally, they are commercialized by a fully

automatic packaging and palletizing line. Unqualified particles are crushed and

returned to the granulation process, forming an efficient closed-loop loop to

improve raw material utilization and product consistency.

3、 List of Key Equipment Configuration

The 50000 ton production line pays attention to the balance between

performance and investment in equipment selection to ensure high efficiency and

reliability.

| 系统模块 | 序号 | 设备名称 | 规格型号/关键配置 | 数量 | 核心作用说明 |

|---|

| 发酵与粉肥系统 | 1-4 | 料仓、双轴搅拌机、链板翻抛机(LXF-5米) | 全自动PLC遥控,液压升降 | 1套 | 为整线提供优 质、稳定的腐熟粉状原料。 |

| 5-8 | 粉碎机(FS1000)、筛分机、粉剂包装机 | 含双包装机头 | 1套 | 构成独立的粉肥生产支线,提升运营灵活性。 |

| 配料混合系统 | 9 | 电脑配料机 | 五仓,触摸屏PLC控制 | 1套 | 配方重 心,实现产品养分的精准与可追溯。 |

| 10, 19 | 双轴搅拌机、链式粉碎机(LP800型) | 出料细度0.7mm | 各1台 | 保障造粒前物料的混合均匀度与超细粒度。 |

| 造粒干燥核心系统 | 11, 12 | 造粒机(ZG-1.8*7)、圆盘造粒机 | 重型铸钢件,不锈钢衬板 | 各1台 | 颗粒成型核心,提供两种造粒方式选择。 |

| 13, 14 | 烘干机 (2.0*20m, 1.8*18m) | 两级串联,耐高温风机 | 2台 | 低温脱水核心,严格控制出口温度保护活性。 |

| 15 | 冷却机 (1.8*18m) | 配大风量风机 | 1台 | 颗粒定型关键,快速冷却以增强颗粒强度。 |

| 成品处理系统 | 16 | 颗粒筛分机 | 含震打装置 | 2台 | 成品分级把关,分离合格品与返料。 |

| 17 | 包膜机 | 可选配 | 1台 | 产品增值设备,用于生产生物有机肥。 |

| 18 | 颗粒自动包装码垛线 | 双机头,高位码垛 | 1套 | 终端效率体现,实现无人化包装,节省人工。 |

| 环保与辅助 | 23-26 | 旋风除尘器、热风炉、除尘室、风管 | 三级除尘系统 | 1套 | 环保达标必备,确保生产尾气清洁排放。 |

Key selection points: The core of the pellet line lies in the granulation, drying, and cooling sections. In this plan, both the dryer and the cooler are made of heavy-duty cast steel and equipped with high-temperature resistant induced draft fans, which ensures the long-term stable operation of the equipment. All motors and reducers use national standard products, and the core components are guaranteed for 3 years without human damage.

4、 Analysis of Investment Benefits and Operations

1. Investment estimation

Equipment investment: The total investment for the core equipment of the

entire production line (including fermentation, powder fertilizer, granulation,

packaging, and environmental protection) is approximately 3.5-5 million

yuan.

Civil engineering support: including fermentation workshop, production

plant, warehouse, and environmental protection facilities, with an investment of

about 1.5-2.5 million yuan, depending on the construction standards.

Total investment: The comprehensive investment for project initiation

usually ranges from 5 to 7.5 million yuan, which belongs to medium-sized

industrial investment.

2. Economic benefit analysis

Production cost: The comprehensive cost of granular fertilizer (including

raw materials, energy consumption, labor, depreciation) is about 450-600

yuan/ton.

Sales price: The market price of granular organic fertilizers varies by

category, ranging from approximately 750-1000 yuan/ton, with higher prices for

organic-inorganic compound fertilizers and bio organic fertilizers.

Profit and return: Calculated at an annual output of 50000 tons and an

average price of 850 yuan/ton, the annual output value can reach 42.5 million

yuan. Deducting costs, the annual gross profit is considerable. Under good

operating conditions, the static investment payback period is approximately 3-4

years.

3. Key to successful operation

Raw material guarantee: Establish a stable raw material collection and

storage system with surrounding breeding farms and planting bases.

Process control: It is particularly important to master core process

parameters such as fermentation maturity, granulation moisture, and drying

temperature.

Market development: Focusing on the characteristics of granular

fertilizers, we will focus on developing customers with high requirements for

fertilizer quality, such as operating areas and cooperatives.

Policy utilization: Actively apply for relevant subsidies for projects such

as the resource utilization of livestock and poultry manure and the

comprehensive utilization of straw.