1、 Project positioning and core characteristics

Scale positioning: With an annual production capacity of 5000 tons, it is

precisely positioned for small-scale breeding farms, family farms, agricultural

cooperatives, or county-level organic fertilizer startups. Its characteristics

are low investment, small land occupation, short construction period, and the

ability to quickly put into operation and achieve benefits.

Product positioning: The core positioning of this production line is to

produce pure organic fertilizer granules. By carefully selecting processes and

equipment, we ensure the production of high-quality granular fertilizers with

good roundness, high strength, and outstanding commodity value on a limited

scale, meeting the needs of segmented markets such as high-end economic crop

planting, flower and seedling cultivation, and home gardening.

Core values:

Low investment threshold and controllable risk: equipment configuration is

streamlined, and the total investment is much lower than that of a 10000 ton

production line, making it easy for small and medium-sized enterprises to

start.

Excellent product form and higher profit: Compared to powder fertilizer,

granular fertilizer is easier to store, transport, and apply, with high market

acceptance and significant sales premium space.

Solving our own environmental problems and creating new income: converting

self-produced or locally collected livestock and poultry manure and other waste

into commodities, turning waste into treasure, killing two birds with one

stone.

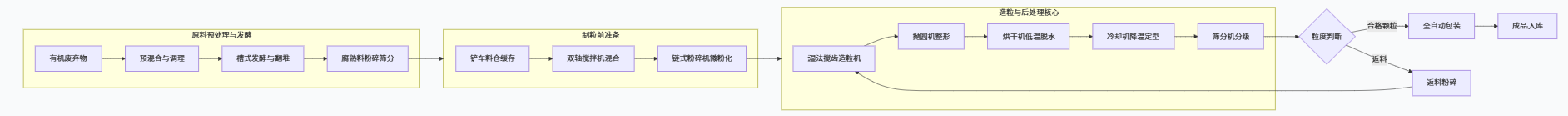

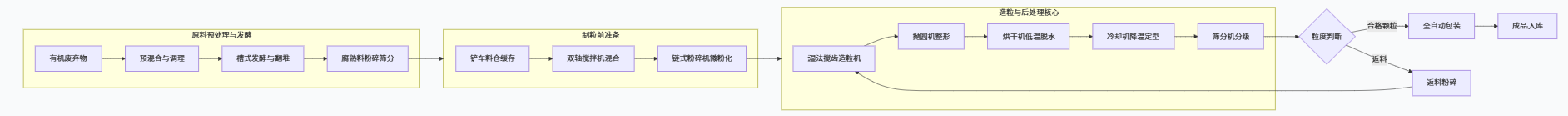

2、 Detailed explanation of core process flow

Although the 5000 ton production line is small in scale, it is fully

equipped with all five organs, covering the core links of granular fertilizer

production: "harmless fermentation, homogenization mixing, and high-quality

molding".

To visually demonstrate the compact process from raw materials to finished

products, the process overview is as follows:

Process Stage Analysis:

Raw material maturation system (safety foundation): After simple mixing of

feces and straw and other auxiliary materials, they are sent to the fermentation

tank. Regularly flipping and throwing by the flipping machine (CFJ3.0), aerobic

fermentation is completed to fully mature and harmless materials, and initially

reduce moisture to produce stable basic organic fertilizer.

Pre granulation material preparation system (uniform guarantee): After

crushing and screening, the decomposed clinker is temporarily stored in the

shovel material bin. Homogenization treatment is carried out through a dual axis

mixer (WZSJ-80), and then finely crushed by a chain crusher (LP60 type) to

ensure material fineness (up to 0.7mm), which is the key to subsequent particle

yield and particle smoothness.

Granulation and post-treatment core system (value creation): this is the

essence of this production line.

Efficient granulation: using the "Wet Stirring Tooth Granulator (JCZL60)".

This model utilizes high-speed mechanical force to agglomerate micro powder

materials into granules with a high granulation rate (≥ 90%), strong

adaptability to pure organic materials, and good particle strength.

Fine shaping: The produced particles immediately enter the "PYS1000

rounding machine" for two-stage rounding, making the particle surface smoother

and rounder, greatly improving the appearance of the product.

Mild drying: A small rotary dryer (GH-1m * 10 meters) is used, matched with

a hot air stove, to achieve low-temperature (≤ 65 ℃) high air flow drying, which

not only removes moisture but also greatly protects the activity of organic

matter.

Cooling and screening: After drying, the particles are quickly cooled and

solidified by a cooling machine (LQ-0.8 meters * 8 meters) to enhance hardness.

Finally, the products are classified by a screening machine. Qualified products

(usually 2-4mm) enter the packaging process, while unqualified products are

crushed and returned to the granulator, forming a closed-loop cycle to ensure

product consistency and reduce waste.

3、 List of Key Equipment Configuration

The selection of equipment for small production lines emphasizes a balance

between practicality, reliability, and cost-effectiveness.

| 系统模块 | 序号 | 设备名称 | 规格型号/关键配置 | 数量(台) | 核心作用与选型要点 |

|---|

| 发酵预处理系统 | 1 | 翻堆机 | YULI-2500履带式翻堆机 | 1 | 小型发酵槽核心,实现物料翻抛供氧,促进腐熟。 |

| 2, 6 | 铲车料仓 | RL16带闸门与隔离网 | 2 | 分别在粉碎前和造粒前缓存物料,保证连续生产。 |

| 3 | 粉碎机 | RFS60,40洛材质刀片 | 1 | 对腐熟后块状料进行初次破碎。 |

| 4 | 筛分机 | RS-1,不锈钢筛网 | 1 | 分离腐熟料中的杂质,得到纯净粉料。 |

| 制粒备料系统 | 7 | 双轴搅拌机 | RJ-10,高锰耐磨螺旋 | 1 | 使物料混合均匀,是保障造粒成分一致的关键。 |

| 13 | 链式粉碎机 | RF5型,出料细度0.7mm | 1 | 造粒前关键设备,将物料微粉化,直接决定成粒质量。 |

| 造粒核心系统 | 8 | 造粒机 | RL7(湿法搅齿式) | 1 | 产线核心。专为有机物料设计,成粒率高,颗粒强度好。 |

| 9 | 抛圆机 | RY20,两级抛圆 | 1 | 提升商品性。使颗粒更圆润、光滑,卖相佳。 |

| 干燥冷却系统 | 10 | 烘干机 | RG-1m*10米,配耐高温风机 | 1 | 低温大风量烘干,严格控制温度保护肥效。 |

| 11 | 冷却机 | RQ-0.8米*8米 | 1 | 快速冷却,增加颗粒硬度,便于储存。 |

| 15 | 热风炉 | 烘干机配套 | 1套 | 提供烘干所需热源。 |

| 成品处理系统 | 12 | 筛分机 | RS-10 | 1 | 对冷却后颗粒进行分级,分离合格品与返料。 |

| 14 | 包装机 | RZ-2型,基恩士传感器 | 1 | 实现成品颗粒的自动计量与包装。 |

| 动力与辅助 | 16 | 控制柜 | 大于15kW电机降压启动 | 1套 | 集中控制,保障电气系统安全。 |

| 17 | 皮带输送机 | RP6型 | 约90米 | 连接各工序,形成流水线。 |

Equipment Highlights: The core equipment of this solution is the "Wet Stirring Granulator", which is particularly suitable for granulation pure organic materials. It has outstanding advantages such as high granulation rate, good particle strength, and low requirements for raw material adhesion. It is an ideal choice for small-scale production of pure organic fertilizer particles.

4、 Analysis of Investment Benefits and Operations

1. Investment estimation

Equipment investment: The total investment for the core equipment of the

complete set of small particle production lines mentioned above is approximately

800000 to 1.2 million yuan.

Civil engineering supporting facilities: including simple fermentation

sheds, production workshops, raw material and finished product storage yards,

etc., with an investment of about 200000 to 400000 yuan and flexible site

requirements.

Total investment: The comprehensive investment for project initiation is

usually in the range of 1-1.6 million yuan, which belongs to small-scale

industrial investment and is very suitable for self owned funds or small loan

operations.

2. Economic benefit analysis

Production cost: The comprehensive cost of small-scale production lines

(including raw materials, energy consumption, labor, and simple depreciation) is

about 400-550 yuan/ton.

Sales price: The market price range for high-quality granular organic

fertilizer is relatively wide, ranging from approximately 700-1000 yuan/ton

depending on the region and market positioning.

Profit and return: Calculated at an annual output of 5000 tons and an

average price of 800 yuan/ton, the annual output value can reach 4 million yuan.

Under stable operation, the static investment payback period is about 2-3 years,

with a short return period.

3. Key to successful operation

Raw material guarantee: Based on our own breeding farm or establishing

stable cooperative relationships with 2-3 small breeding farms in the

surrounding area, we can meet the demand for raw materials.

Process mastery: Focus on mastering core parameters such as fermentation

moisture control, pelletizer feed rate and moisture addition, drying

temperature, etc.

Market Focus: The product can focus on "high-quality granular organic

fertilizer", targeting high-end users such as surrounding fruit and vegetable

greenhouses, tea gardens, flower bases, landscaping, and home gardening, and

implementing differentiated competition.

Flexible operation: The production line can also accept processing services

for incoming materials, processing manure for surrounding farmers and turning it

into granular fertilizer to earn processing fees. The mode is flexible.