1、 Project Overview and Core Values

The aim of this project is to construct a production line for powdered

organic fertilizer with an annual output of 10000 tons. Through standardized and

mechanized treatment processes, organic waste such as livestock manure, crop

straw, and urban sludge will be converted into high-quality powdered organic

fertilizer.

Project positioning and market: With an annual production capacity of 10000

tons, it is an ideal choice for medium-sized agricultural and animal husbandry

enterprises, regional environmental protection companies, or professional

fertilizer producers to invest. It has economies of scale and can effectively

cover a prefecture level market.

Wide adaptability of raw materials: The core process is suitable for the

harmless treatment and resource utilization of various organic solid wastes such

as cow manure, sheep manure, pig manure, chicken manure, sludge, rice straw,

corn straw, etc.

Core values:

Economic benefits: turning waste into treasure, creating significant

product profits, low raw material costs, and reasonable return period.

Environmental benefits: Addressing the issue of waste disposal in

large-scale aquaculture and urban waste management, in line with national

environmental policy guidance.

Agricultural benefits: The organic fertilizer produced can improve soil

structure and enhance crop quality, which is an important guarantee for the

development of green and organic agriculture.

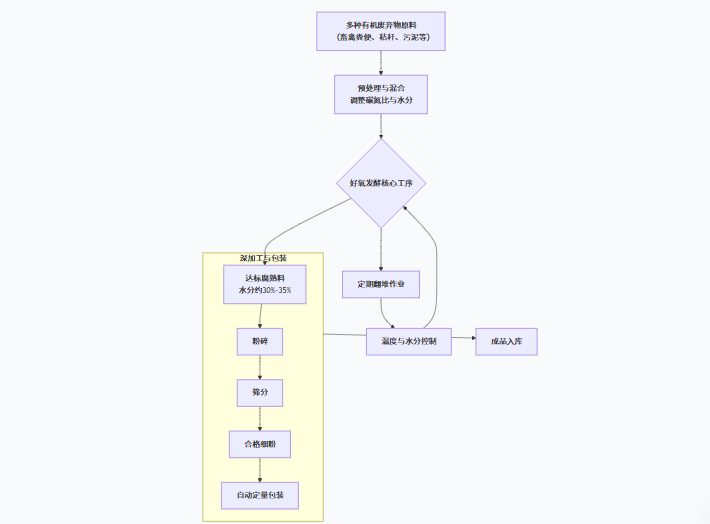

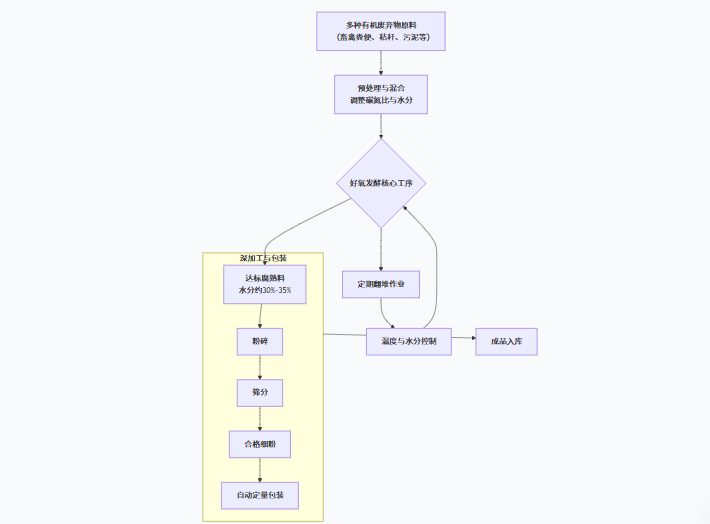

2、 Detailed explanation of core process flow

The entire production line follows the scientific process of "fermentation

and maturation → crushing and screening → packaging and storage" to ensure the

safety, stability, and efficiency of the products.

Flowchart: Production process of 10000 tons of powdered organic fertilizer

per year

1. Preprocessing and mixing ratio

Mix the collected main materials such as feces and straw with auxiliary

materials (such as microbial agents and conditioners) in scientific proportions.

The goal is to adjust the carbon to nitrogen ratio of the initial material to

25-35:1 and control the moisture content at 55% -65%, creating optimal

conditions for subsequent aerobic fermentation. This process can be completed

with the help of a shovel or premix equipment.

2. Aerobic fermentation and maturation (core process)

This is a crucial step in determining the quality and safety of

fertilizers. The mixed materials are sent into the fermentation tank, and under

the action of the "tank type stacker", the materials are regularly and evenly

flipped and thrown.

Mechanism of action: Injecting oxygen into the material by flipping it over

promotes the proliferation of aerobic microorganisms. The temperature of the

material quickly rises above 55 ℃ and is maintained for 5-7 days, effectively

killing pathogens, insect eggs, and grass seeds, achieving harmless treatment.

At the same time, organic matter is decomposed and converted into stable

humus.

Process control: The fermentation cycle is usually 15-25 days, and the

moisture content of the material can be reduced to 30% -35% after fermentation

is completed.

3. Deep processing and packaging

The decomposed materials enter the processing workshop.

Crushing: A chain crusher is used to crush block shaped clinker, ensuring

uniform particle size and easy subsequent processing and application.

Screening: The crushed material is classified by a drum screening machine,

and the qualified fine powder enters the next stage as the finished product,

while the coarse material is returned for re crushing to ensure consistent

product fineness.

Packaging: The finished powdered fertilizer is transported by a conveyor to

a fully automatic quantitative packaging machine, where it is accurately

measured (usually 20kg/bag or 40kg/bag) and sealed before being stored or

sold.

3、 List of Key Equipment Selection and Configuration

Equipment is the backbone of the production line. The following

configuration is designed specifically for an annual output of 10000 tons to

ensure production capacity and quality. Among them, the selection of turntables

and crushers is particularly crucial for overall efficiency.

| 序号 | 设备名称 | 推荐型号/规格 | 核心功能与技术要点 | 数量(台) | 建议功率 (kW) |

|---|

| 1 | 履带翻堆机 | YULI-2500 | 发酵核心设备。负责翻抛供氧、散热、匀质。需采用重型底盘和耐用拨齿,以应对长期高负荷作业。 | 1 | 18.5+0.75 |

| 2 | 铲车料仓 | CWL1530 | 缓存与均匀给料。置于粉碎机前,确保连续生产,并配有破拱装置解决物料架桥问题。 | 1 | 3+2.2 |

| 3 | 粉碎机 | LF360 | 深加工关键设备。对腐熟料进行破碎,其链式结构不易粘壁,特别适合湿度较大的有机物料。 | 1 | 18.5 |

| 4 | 滚筒筛分机 | GT-2 | 产品分级。分离成品与返料,提升产品外观一致性。筛网应便于更换。 | 1 | 3 |

| 5 | 自动包装机 | ZB-6 | 成品定量包装。高精度传感器保证计量准确,“快、中、慢”三档下料确保包装速度与精度。 | 1 | 0.92 |

| 6 | 皮带输送机 | S-5 | 物料传输纽带。连接各工序,形成流水线。需根据工艺布局确定长度(如3条30米)。 | 3 | 9(合计) |

| 7 | 控制柜 | - | 系统集中控制。实现一键启停,并对主要电机进行过载、缺相保护。 | 1套 | - |

Explanation: In the above equipment configuration, it is recommended to use

national standard products for core components such as motors and reducers, and

clarify with the supplier the warranty period for key equipment (such as

turntables and crushers) (3 years if not damaged by human factors) to ensure

long-term stable operation.

4、 Feasibility analysis and investment benefits of the project

1. Market and policy feasibility

Market demand: With the increasing demand for soil improvement and the

improvement of agricultural product quality, there is a huge market space for

high-quality organic fertilizers.

Policy Dongfeng: The government has clear financial subsidies and tax

incentives to support projects such as the resource utilization of livestock and

poultry manure and the comprehensive utilization of straw.

2. Economic benefit analysis (estimate)

Investment estimation:

Equipment investment: The core equipment investment for the complete

production line mentioned above is approximately 450000 to 650000 yuan.

Civil engineering investment: including fermentation workshop (sunroof or

enclosed), processing workshop, warehouse, etc., requiring approximately 300000

to 500000 yuan.

Total investment: usually between 800000 and 1.2 million yuan, depending on

the degree of automation and factory standards.

Costs and benefits:

Production cost: mainly includes raw materials, electricity, labor,

bacterial strains, packaging bags, etc., with a comprehensive cost of about

350-500 yuan/ton.

Sales revenue: Calculated based on the average market price of 600-850

yuan/ton for powdered organic fertilizer, with an annual output of 10000 tons,

the annual output value can reach 6-8.5 million yuan.

Profit analysis: The annual gross profit is approximately 2.5-3.5 million

yuan. Under good business conditions, the static investment payback period is

about 2-3 years.

3. Environmental Protection and Social Benefits

The project itself is a typical environmental protection project that can

effectively solve the problem of regional organic waste pollution.

The product can improve soil, reduce fertilizer usage, and has good

ecological cycling benefits.

4. Potential risks and countermeasures

Raw material supply risk: Long term and stable raw material storage and

transportation agreements need to be established with surrounding breeding farms

and planting bases.

Product quality risk: Establish strict production process monitoring

(especially fermentation temperature and time) and factory inspection

system.

Market sales risk: In the initial stage, the "demonstration

field+agricultural technology service" model can be adopted for promotion,

actively connecting with channels such as cooperatives and family farms.