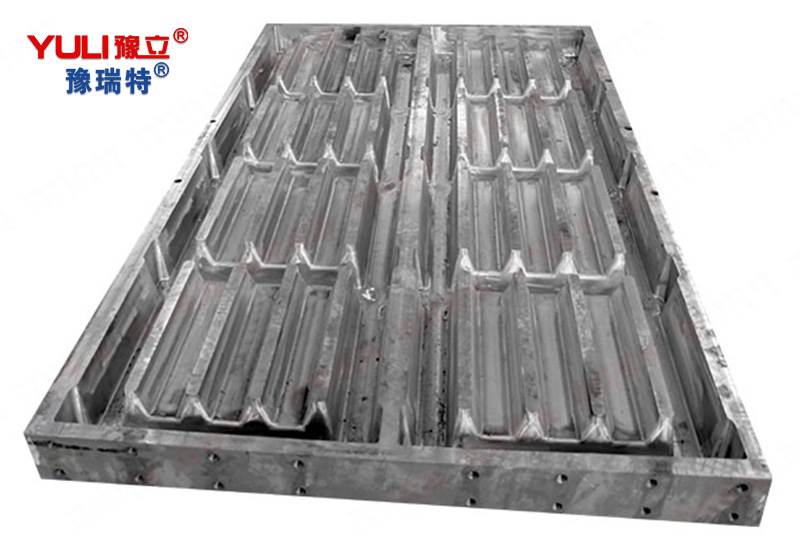

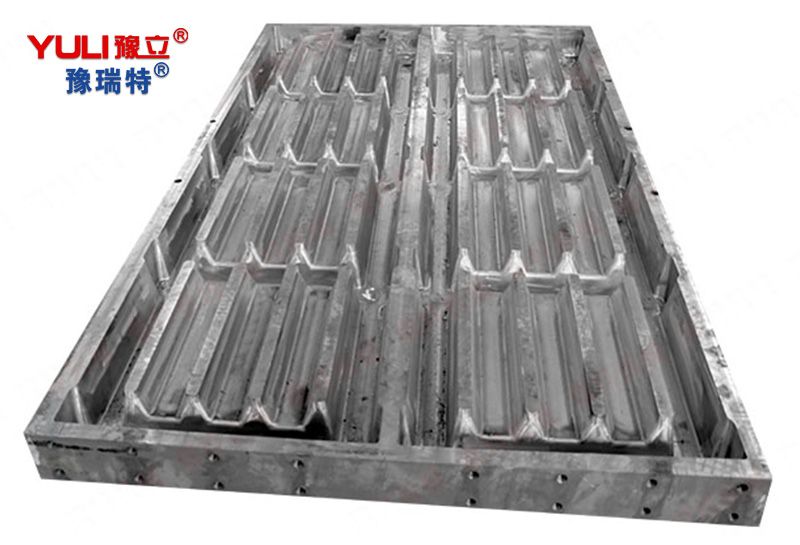

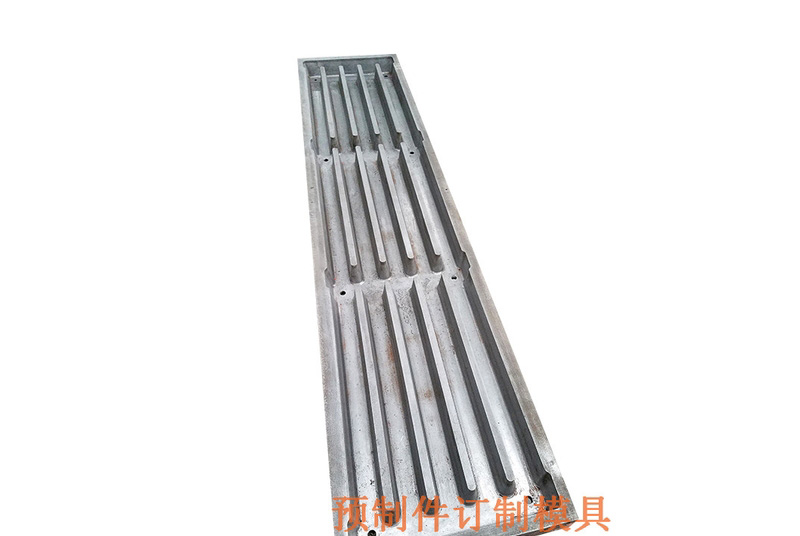

1、 Core advantages and characteristics of 2400 pig fecal leakage plate

mold

High precision and standardization

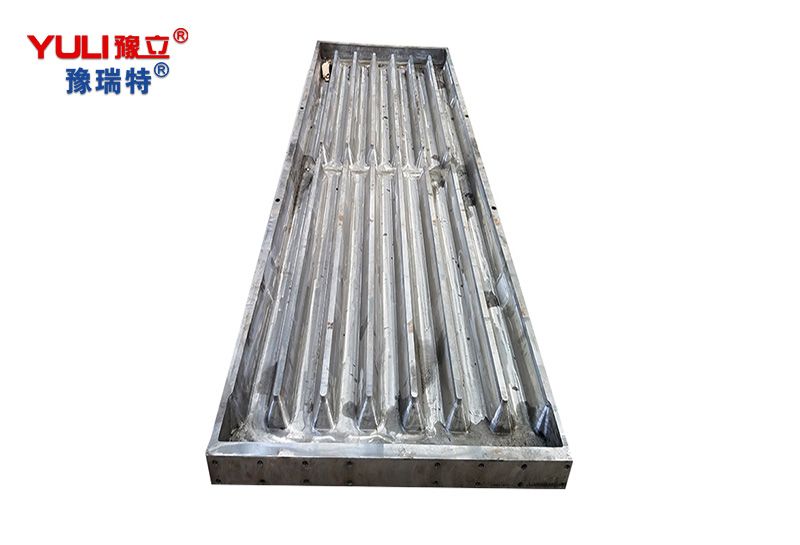

Accurate size: Made using CNC cutting, laser cutting, CNC machining centers

and other processes, the size error is extremely small (usually within ± 0.5mm),

ensuring that each piece of leakage plate produced has a uniform size, excellent

interchangeability, and is easy to install on a large scale.

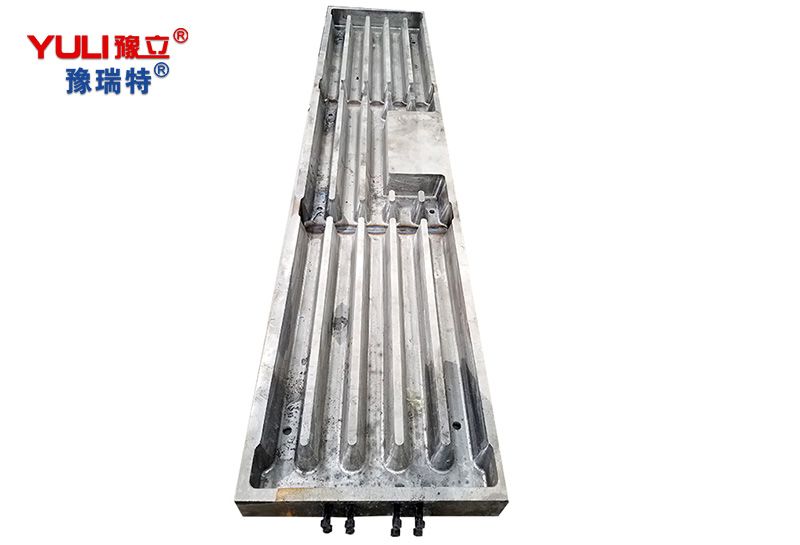

Uniform gaps: The width, spacing, depth, and height of the leakage holes

are consistent, which is the key to ensuring product functionality (effective

leakage without damaging livestock hooves) and appearance quality.

Excellent product surface quality

Mirror finish: The working surface of the mold cavity is finely polished

and/or chrome plated to achieve a mirror effect. This makes the surface of the

cement leakage board after demolding exceptionally smooth, effectively

preventing damage to the skin and hooves of livestock, and making it difficult

for feces to adhere, making it easy to clean.

Clear edges: The edges and ribs of the product are straight and distinct,

and the appearance is neat and beautiful.

Extremely high durability and long lifespan

Durable Material: Made of high-quality carbon structural steel (such as

Q235A) or alloy steel plates, with sufficient thickness (usually 8-12mm or more

for panels), extremely strong rigidity, and no deformation.

Wear resistance: Cement slurry causes significant wear on molds, while the

high hardness and surface treatment of steel (such as chrome plating) can resist

wear. A set of high-quality steel molds can be recycled tens of thousands to

hundreds of thousands of times, diluting the cost per piece.

Extremely high production efficiency

Quick demolding: Designed with a scientific demolding slope (usually 0.5 °

-2 °) and equipped with a hydraulic or mechanical ejection system, it can

achieve fast and non-destructive demolding with a fast production cycle.

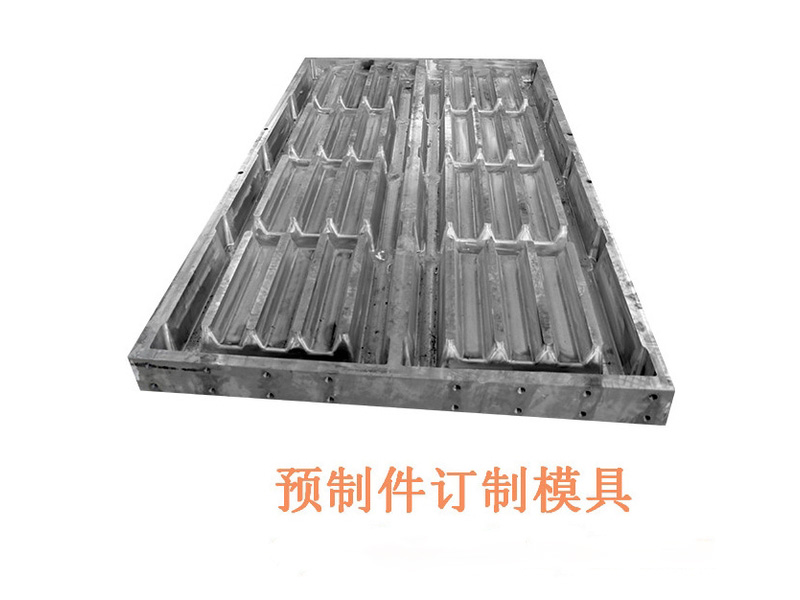

Multi link design: Multiple boards (such as 2-link, 4-link, 6-link) can be

formed simultaneously within one mold frame, with one pouring, doubling the

output.

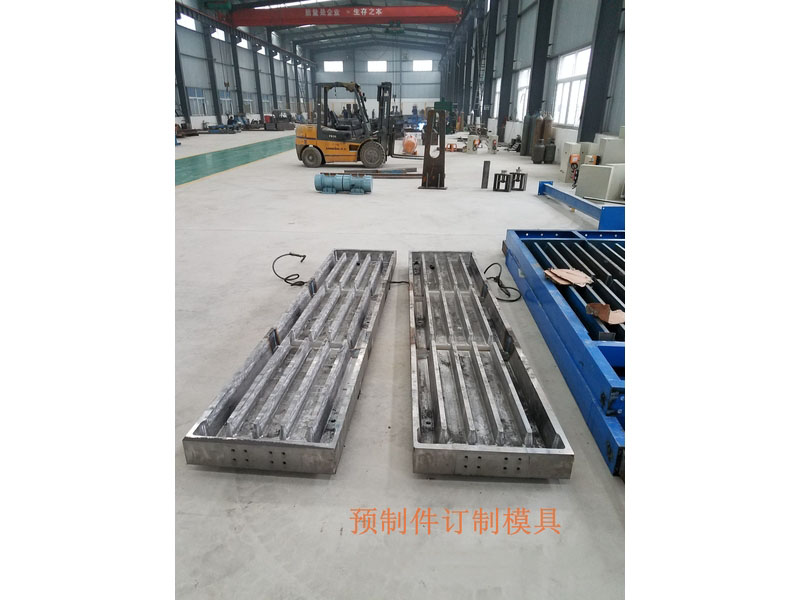

Adaptive assembly line: It can be combined with concrete laying machines,

high-frequency vibration tables, steam curing kilns, mechanical arms, and other

automated production lines to achieve continuous operation, with a daily output

of hundreds or thousands of pieces.

Structural Design Science

Reinforced rib plate: The back of the mold is welded with dense reinforcing

ribs to ensure stability and prevent deformation during frequent vibration,

pressure, and lifting processes.

Positioning and locking: Precise positioning pins and quick locking

mechanisms are used to ensure that the mold fits tightly and seamlessly without

leakage, and the product thickness is consistent.

Modular design: The "leakage gap strip" of some high-end molds is designed

as a replaceable independent module, which can produce plate shapes with

different gap widths by replacing the module, achieving multi-purpose and high

flexibility for one machine.

35f16758-db0c-4ac8-93df-2730fc055b8c

2、 Classification and specific type characteristics

According to different production processes, the 2400 pig fecal leakage

plate molds can also be divided into:

Flat mold for vibration table:

The mold is open and placed on a vibration table. After pouring concrete,

it is compacted by high-frequency vibration.

Characteristics: The structure is relatively simple, with strong

universality, and it is the most common type.

Formwork (with side vibration):

The mold is erected vertically, poured from the side, and cured by

vibration in a vertical state.

Features: The boards produced are smooth on both sides, the steel

reinforcement protection layer is controlled extremely evenly, the compactness

is high, and the product quality is the best. But the equipment investment is

large and the process is complex.

3、 Comparison with traditional simple molds

| 特性 | 钢制专 业模具 | 传统木模/简易钢模 |

|---|

| 精度与一致性 | 极高,标准化产品 | 差,依赖人工,误差大 |

| 表面光洁度 | 镜面效果,不伤畜体 | 粗糙,需二次抹面 |

| 生产效率 | 极高(自动化/半自动) | 极低(完全人工) |

| 产品强度 | 高(机械振动密实) | 低(人工振捣不均) |

| 模具寿命 | 数万次以上 | 几十到几百次 |

| 初始投资 | 高 | 极低 |

| 适用场景 | 大型预制件厂、规模化养殖场自建车间 | 家庭作坊、零星修补 |

4、 Application and selection points of 2400 pig fecal leakage plate

mold

Clear requirements: Select the type and number of molds based on the

specifications (length, width, thickness, gap), material (ordinary

concrete/reinforced type), and expected production volume of the planned fecal

leakage board.

Inspection process: Focus on the steel thickness, rib density, welding

quality, internal cavity smoothness, and demolding mechanism design of the mold.

A good mold should be "silly, big, heavy, and thick", with solid materials.

Matching production line: The mold must match the existing or planned

fabric machine, vibration table, and maintenance facilities, especially the

installation size and demolding method.

Customized services: Legitimate manufacturers provide drawing confirmation

and customized services, which can be designed according to your special needs

(such as specific brands, logo imprints).